Top Benefits of Using a Membrane Switch in Custom Control Panels

Top Benefits of Using a Membrane Switch in Custom Control Panels

Blog Article

Why Membrane Change Modern Technology Is Vital for Industrial Applications

Membrane layer button innovation plays a pivotal function in enhancing functional efficiency across various industrial sectors. Its fundamental resilience and resistance to environmental stress factors make it particularly appropriate for demanding applications, while its small layout promotes seamless integration right into devices. Additionally, the modification choices offered not just provide to certain useful requirements but additionally contribute to branding efforts. As sectors significantly seek ingenious options to boost user communication and productivity, recognizing the subtleties of membrane button modern technology ends up being important. The ramifications of these advancements may be extra considerable than initially regarded.

Overview of Membrane Change Technology

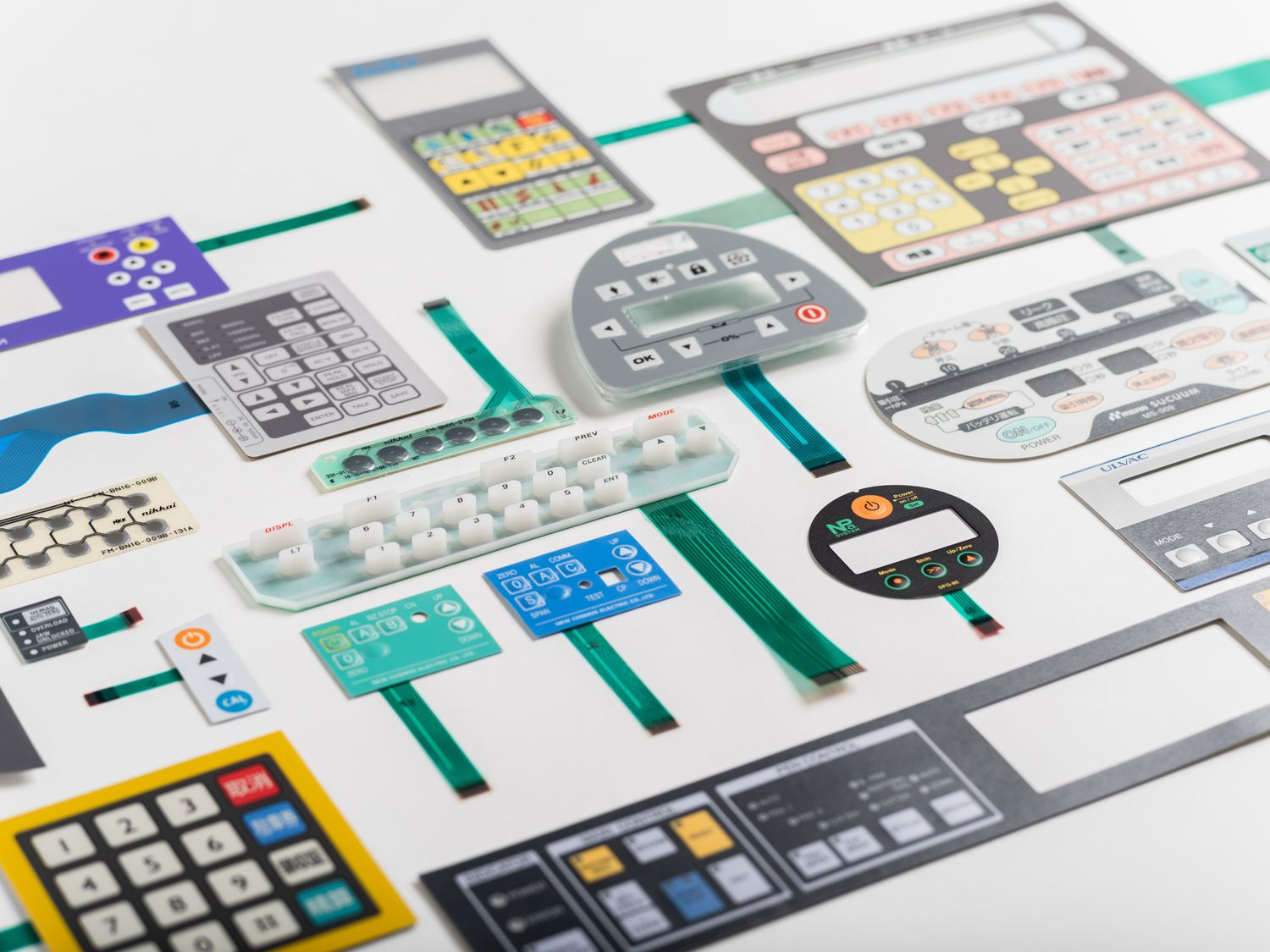

Membrane switch modern technology is significantly recognized for its convenience and efficiency in industrial applications. This innovation makes use of a slim, adaptable membrane layer that functions as an individual interface for various digital tools. Comprising multiple layers, a regular membrane layer button includes a graphic overlay, a spacer layer, and a circuit layer, enabling a resilient and small layout. The layers are published and laminated flooring to create a durable user interface that can endure extreme environments.

Membrane changes feature tactile comments, giving individuals with a recognizable feedback upon activation. They can be tailored with numerous graphics, colors, and backlighting alternatives to boost use and branding. In addition, membrane buttons are resistant to dampness, dust, and chemicals, making them optimal for demanding industrial setups.

This technology likewise sustains assimilation with a series of systems, consisting of control board and equipment, helping with smooth interaction between drivers and devices. In addition, the lightweight and low-profile nature of membrane layer switches over adds to space-saving styles in control systems (membrane switch). Overall, the ingenious design and practical benefits of membrane layer switch innovation make it a valuable option for enhancing operational effectiveness in commercial applications

Trick Advantages for Industrial Usage

The secret advantages of membrane button technology for commercial usage are various and considerable, making it an attractive alternative for various applications. Among the primary advantages is their sturdiness; membrane buttons are designed to stand up to rough environments, including exposure to chemicals, dampness, and severe temperatures, making sure trusted performance over time.

Additionally, their small layout enables for flexible assimilation into a wide variety of devices and machinery, optimizing space without jeopardizing functionality. The versatility in style choices makes it possible for personalization to fulfill details individual demands, enhancing usability and aesthetic allure.

Membrane layer buttons are additionally reasonably very easy to make, which can result in affordable manufacturing for high-volume applications. Moreover, their lightweight nature contributes to overall energy effectiveness in tools operation, minimizing the power impact of commercial systems.

Applications in Different Industries

Making use of membrane layer switch innovation throughout different industries showcases its versatility and performance in conference varied functional needs. This technology is widespread in fields such as health care, auto, and production, where effectiveness read what he said and dependability are paramount.

In the health care industry, membrane switches are typically used in analysis equipment, monitoring devices, and individual monitoring systems. Their capacity to stand up to constant cleaning and direct exposure to severe chemicals makes them excellent for maintaining health requirements. In automobile applications, membrane buttons are employed in control panels, control panels, and infotainment systems, allowing for instinctive customer interaction while ensuring sturdiness under differing ecological problems.

The production field also benefits substantially from membrane button innovation. These switches are integrated into equipment controls, automation systems, and equipment interfaces, providing operators with a find this reliable and seamless ways of regulating complex processes. Their portable layout enables space-saving solutions, which is particularly useful in devices where real estate is limited.

Customization and Style Choices

Customization and layout choices play an important function in the efficiency of membrane switch technology for commercial applications. The capability to customize membrane layer buttons to meet details operational demands is essential for enhancing user experience and guaranteeing capability. Manufacturers supply a vast array of modification possibilities, consisting of differing sizes, forms, and layouts, which enables for seamless assimilation into different industrial atmospheres.

In addition, membrane layer switches can be developed with diverse materials, such as polyester or polycarbonate, to stand up to harsh problems, consisting of heats, dampness, and chemical exposure. Furthermore, graphic overlays can be customized to consist of special branding aspects, signs, or color schemes, guaranteeing that operators can quickly recognize controls also in low-light or high-stress circumstances.

Trick layout alternatives additionally incorporate responsive comments systems, backlighting, and the incorporation of numerous switch modern technologies such as capacitive or resisting touch. These features not just improve functionality yet also boost the longevity and integrity of the product. Eventually, the flexibility in modification and style choices makes membrane layer button innovation a vital asset for sectors seeking to maximize their operational performances and enhance individual communication.

Future Trends and Innovations

As sectors proceed to develop, there is a growing focus on incorporating innovative innovations into membrane layer switch layout, leading the way for future fads and advancements. One considerable fad is the consolidation of smart modern technologies, such as touch-sensitive interfaces and haptic responses, improving user communication and functionality. This assimilation allows for even more intuitive control systems, specifically in complicated industrial atmospheres.

Furthermore, advancements in products science are leading to the advancement of even more durable and eco-friendly membrane layer switches. Innovations such as published electronics and versatile substratums are improving the efficiency and long life of these devices, making them appropriate for rough conditions common in commercial settings.

An additional arising pattern is the fostering of IoT (Net of Things) capabilities within membrane layer buttons. membrane switch. This connection allows for real-time data collection and tracking, enabling predictive maintenance and improved functional click efficiency

Furthermore, personalized software application user interfaces are coming to be progressively preferred, supplying users with the capability to tailor capabilities to particular applications, thus boosting general use. As these patterns remain to establish, membrane layer switch technology will play a critical role in shaping the future of commercial applications, driving effectiveness and innovation throughout various markets.

Final Thought

To conclude, membrane layer switch modern technology plays an important duty in boosting operational efficiency throughout diverse commercial applications. Its robust design, resistance to environmental difficulties, and customizable attributes make it an ideal selection for sectors such as production and health care. As sectors continue to develop, the combination of advanced responsive comments and innovative performances will certainly further drive productivity and interaction. Eventually, the recurring developments in membrane button innovation will certainly strengthen its position as a fundamental part in commercial environments.

Membrane switch technology plays an essential function in boosting operational performance throughout different commercial fields.Membrane layer switch innovation is progressively acknowledged for its adaptability and effectiveness in commercial applications. On the whole, the cutting-edge layout and functional benefits of membrane button technology make it a useful option for enhancing functional effectiveness in commercial applications.

Customization and layout choices play a crucial duty in the performance of membrane layer button technology for industrial applications.In conclusion, membrane switch technology plays an essential role in enhancing functional efficiency throughout diverse industrial applications.

Report this page